Banyandah is an aboriginal word meaning “home on the water” that we chose from a book brought to our house by Jack’s first boss in Australia who supported our building a vessel.

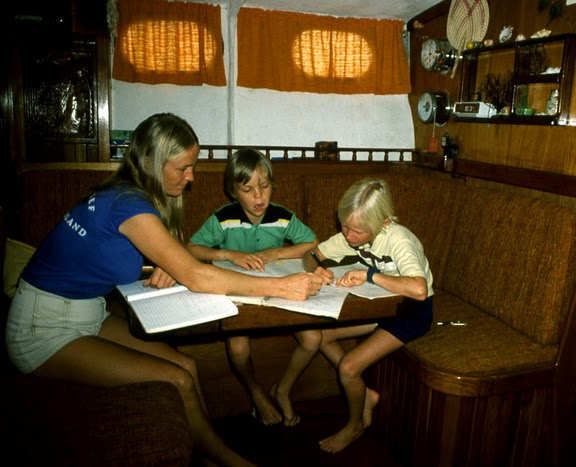

Jude had just given birth to our first child, Jason, and was pregnant with Jerome. So indeed, “home on the water” seemed quite appropriate.

Construction ~

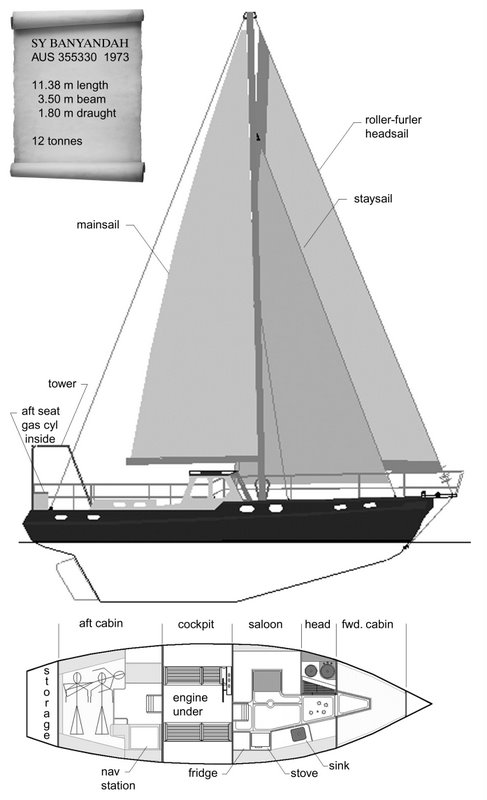

Banyandah was backyard built in Sydney. Construction began in late 1970, we launched June 1973. There is a detailed work diary around somewhere, but from memory, she took about 10,000 hours to complete and cost $15,000 back then. But we built everything, and to keep costs low, we sailed away with little gear.

Her first rig used heavy galvanized wire to support our steel tube mast we welded together, complete with steps one weekend. That rig proved exceptionally strong, surviving a roll over when crossing the Pacific in winter near 50° north.

Her original fit-out featured Fijian Cedar veneer ply bulkheads with poor man’s teak for trim. That’s what we called Black Bean timber back then. Her power-plant, a straight six Perkins, we took out a truck and rebuilt. Heavy, but reliable. She carries 700 litres of fresh water in four separate tanks and about 500 litres of diesel in two twin interconnected SS tanks. She’s built for long distance cruising.

Voyages ~

From first launch in 1973 until 1990, Banyandah was the “home on the water” for the Four J’s – who sailed around the world in ever-increasing circles, exploring Earth while educating their sons. Banyandah sailed more than 120,000 nautical miles, crossed four of the five oceans, and provided living quarters for our family while visiting 80 countries around the world. The Galapagos and Easter Island stand out, and our seven months living in Japan fascinated us.

In 1990, we craned her from the water and lived aboard her on our front lawn while building our first land-based house. During the next 16 years, she was totally gutted, sandblasted, epoxied, and rebuilt from the keel up with new systems and then re-launched in 2005.

Banyandah’s major assets: clean deck – strong dodger – solid railing

Galley Forward, SS working surface, Red Cedar with Rosewood trim

Aft cabin with double bed

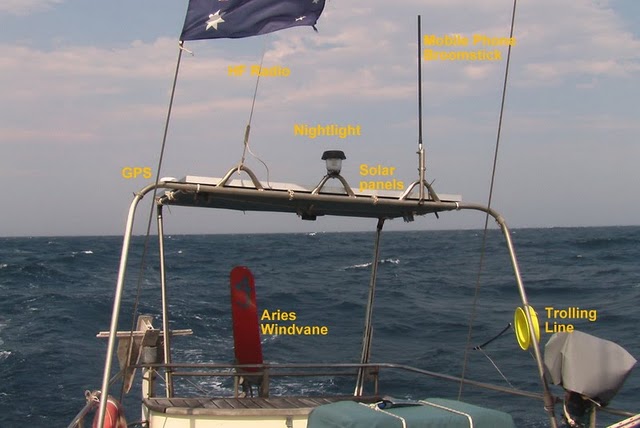

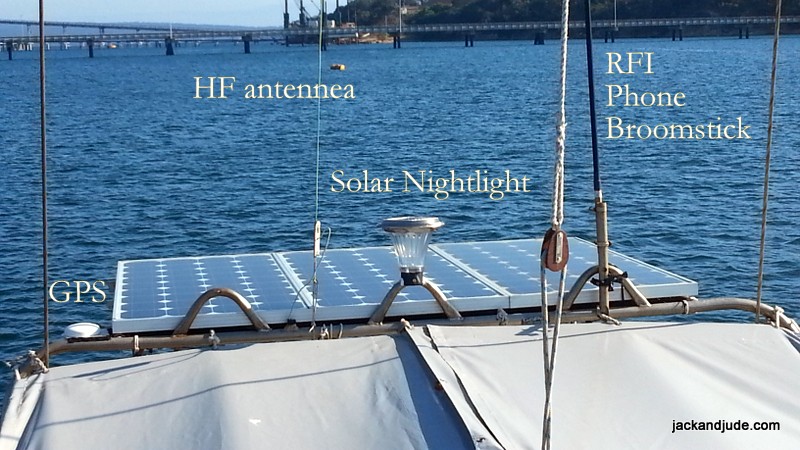

Our new aft deck tower

Hi Jack and Judith, Ian Kirk formerly of Wyuna here.(Hartley Queenslander.) We met at the Keppell’s in 1974. When living at Lennox head we called in one day and saw Banyandah in the front yard but no-one was at home.

Great to see she and you both are still cruising.

I remember seeing Jason at Skillshare Ballina once and thought Jack had spent time teaching maritime studies in Tassie. Hope you’re all well.

I’ve down sized to cruising Moreton Bay in an 11′ sailing dinghy now. Cheers, Ian.

Sorry for the late reply. We must have been away when it came in, but we’d love to get together again. Drop us an email with your contact details and lets chat. All good here.

Hi I’m just buying a Swanson 28 called…Banyanda! I really like the name & would like to keep it but would like to ask is your great yacht Australian registered with the name? I’m going to live aboard & get her Australian registered. Regards Mark Elliot-Ranken

Good Luck Mark! May the wind take you on many an adventure. Answering you query, Yes Banyandah is Australian Registered 355330 – There are several Banyandah in Australia, means ‘Home on the Water” and we are not the first! Our registered name is “Banyandah 1973” the year we launched our vessel. Hope that helps.

Hi

Was this Ketch designed by J. MEYER, SYDNEY?

Hi guys just of interest on the comments rolling if you look up Captain Voss 1901 he circumnavigated the world in a modified 38ft canoe, he makes comment on how as a young midshipmen he loaded the vessel to deep making it roll badly even on the canoe he carried shifting sand ballast that he moved around on deck to steady her out.

Loved your podcast Jack and your views on life please don’t make my comment public

Hi Jack & Jude,

The photo you have of Hartz Mountain in SE Tasmania is actually Adamsons Peak from Esperance Bay, Dover.

In regard to sandblasting of ferro hulls I had also read that it was a no no.

In Colin Brookes book Ferro Cement Boats he stated that you shouldn’t sandblast ferro, I’m not an expert of ferro but I cant see it being a problem with a good operator who only takes off the paint.

Regards, Max

Greeting from Maryland here in the States. I listened to you interview on the

sailing podcastearlier this year and want to get more information on your boat build process. I have designed a cruising yacht out of necessity (I’m 6′-6″ 1.93m tall and built like an American footballer). I want a boat that I fit in comfortably and that would be safe for me while passage making; I don’t want to be knocked unconscious in a rough blow because the bulkheads are all 6 foot. I plan to build this boat myself in my back yard. Like you I am of regular means and plan to do most of the work myself. Have you cataloged your boat build process in any of your publications? Thanks for the opportunity, keep up the great work. KamauGday Jack & Jude

A quick thank you for the cruising guide I received.

Oh and did you build Banyandah next to the intersection of Wakehurst Parkway & Dreadnought Road.

regards Richard

Hiya Jack and Jude

I’m in the market for a broadband marine antenna for my yacht and was wondering what you guys use and if it works well???…I will only use it for internet weather etc….I’m looking at the AN1600 with 8dbi….Any comments????

Cheers, Scott

Jack & Jude,

I have just been told about you and your website today. Extraordinarily 2 years ago I purchased a timber Motorsailer called “Banyandah”, 30′ long, 10′ beam and 1.6m draft, built in 1965 by Hancock in Ballina.

On looking at your “Banyandah”, she is basically the same design – I was astounded!

If you would like to exchange more info, I would be happy to receive an email direct.

Good day Wesley in Whangarei, The South Seas does not have a very high ballast to weight ratio, but Banyandah is not that tender nor rolly. She has the deep draft at 1.8 m and ballast only between the two frames forward of the engine. Originally we carried extra trim ballast right aft, but have removed it as we shifted weight aft. Static ballast would be only a few tonnes at most. If you roll excessively, check your weight aloft and in the superstructure. Are deep draft? Are your topsides ferro? Jack

Glad to make your acquaintance!

I have been working on a South Seas , that took 30 years to be launched. Interesting story. I have a question. My ship, the Ruby Dawn, has proven to be a real roller, gunnel to gunnel, with a following sea, or in a rolly anchorage, or motoring without the mainsail. I think she is short on ballast. Only ballast is in the two frames forward of the engine compartment. We have a center cockpit and wheel house. How much ballast do you have, and how may frames is it spread over? Thanks for any ideas,

Wesley in Whangarei NZ

Wow. That new interior is a fantastic step up from the original. She’s absolutely gorgeous. It’s awesome that you built her from scratch; She’s a gorgeous lady.

Just wanted to say your Blog is in my rss you got a way with words.. Cheers,

Hello Jack,

Thanks for responding to my enquiry on sandblasting the hull. Can you tell me how you went on to repair any damaged areas once the sandblasting was finished.

So it was good to find your blog and read that you had sandblasted the hull with no ill effects.

Bill

Hi Bill

I’ve never heard it was considered a no no to blast a ferro hull.

If the ferro is good, then its hard and blasting will get rid of the coatings leaving a clean hull, in our case, we soaked that clean hull in raw epoxy the same day.

Where it was weak, around the bilge area, chain locker and where a hatch leaked, the blasting ate into the ferro, which is just what I wanted.

Of course, you need a man with some finesse. My man didn’t seemed to have any trouble at all. I had him go inside and blast that too. Coated both side of the hull after that.

Banyandah had already sailed 120K by this time, maybe more, and she was nearly 20 years old. Since then, she’s clocked another 20k hard miles in southern latitude.

Cap’n Jack

G’day Jack and Jude,

Banyandah looks to be a real nice, well cared for Ferro yacht, just the type of Ferro yacht I hope to own within the next year…Or less.

I found your statement interesting, when you say, you sandblasted the hull. I’ve read on, ferrocement.org I think it was, that sandblasted a FC hull is a big no-no. I’m sure others, besides myself, would be interested in hearing how you went about sandblasting and treating your Ferro hull.

Thank you for the good information.

Bill